Hemp Can Still Save the World

How Jack Herer was right – and Ed Rosenthal was wrong – about hemp ethanol.

So if you watch the news these days – or even the talk show comedian version of the news – you might notice the world is on fire. The forests are burning and the icecaps are melting and the ocean levels are rising and the seas are warming and there’s a massive die off of animal life and nobody seems to know what to do about it. I’ve been thinking about this – and doing research on it – for a long time, and I have a few thoughts. The first thought is that one should familiarize one’s self with the problem of human-caused climate destabilization – I have a link here that will provide you with the basics.

The second thing you should do is to look into solutions. Not the “release a virus and kill half of humanity” type of solution, and not nuclear power, either – that’s a scam.

The solution to human-caused climate destabilization is hemp ethanol. What is hemp ethanol, you ask? Read on …

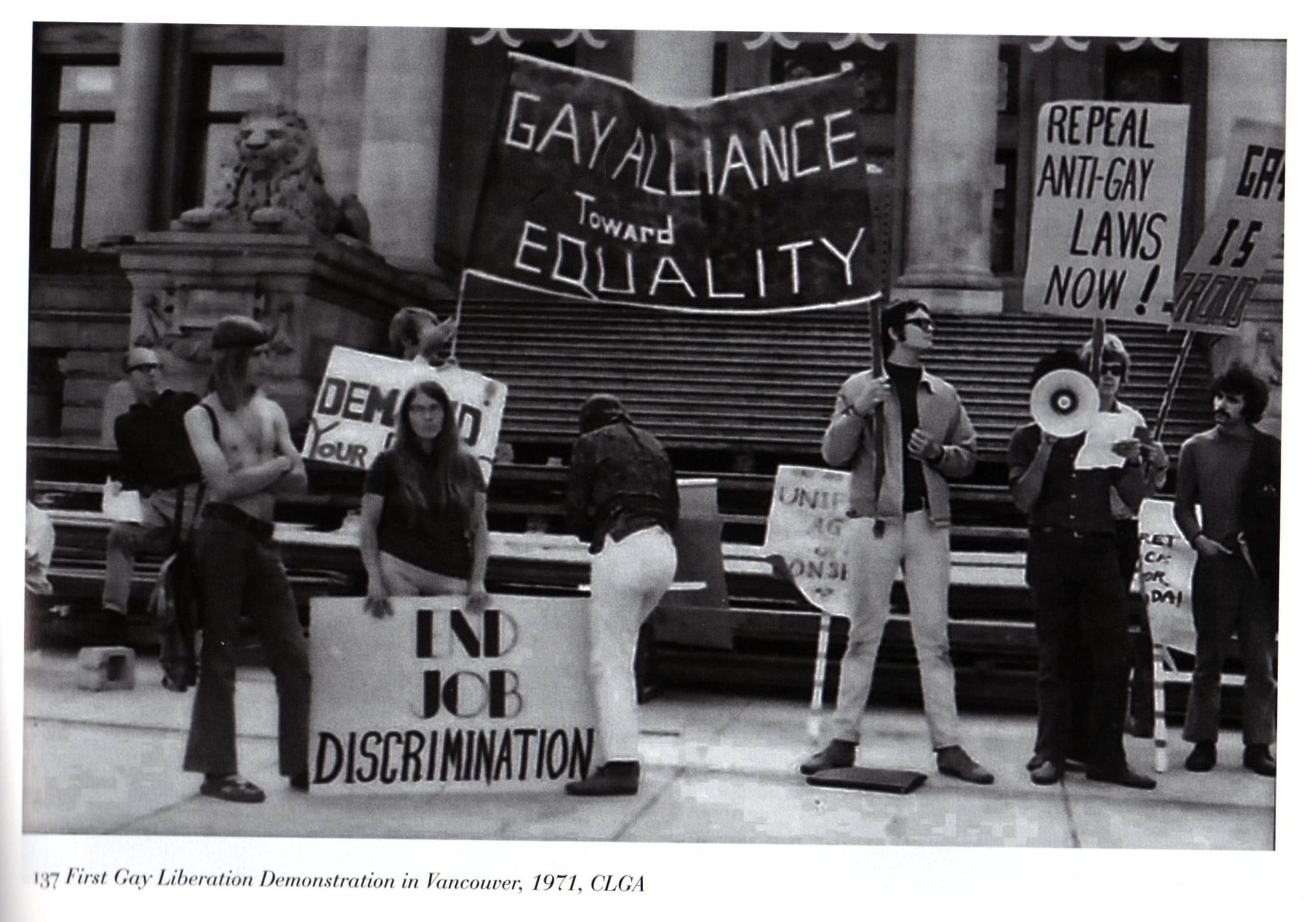

The Emperor Wears No Clothes, Jack Herer, first edition, 1985

In 1985, Jack Herer published the first version of his epic work, “The Emperor Wears No Clothes”. It was a collection of facts about cannabis that had never been assembled before in one package.

Facts such as how it could provide the best medicine, best food, best fabric, the best construction material and the best fuel on Earth – and how the government has been lying about it’s supposed dangers for decades. He distributed “Emperor” all over the United States – sometimes right outside high schools – which got media attention.

The most subversive thing about Herer’s book was the part where it talked about climate destabilization and Hemp’s ability to re-stabilize the climate;

“The book Solar Gas, 1980, Science Digest; OMNI Magazine, The Alliance for Survival, The ‘Green Party’ of West Germany and others, put the TOTAL figure of our energy costs at eighty percent of our TOTAL dollar expense of living for each human being. … eighty-two percent of the TOTAL value of all issues traded on the New York Stock Exchange, other world stock exchanges, etc. are tied directly to 1) energy supply companies (oil, Exxon, Shell, etc.), wells/coal mines, (Con Edison, and so forth); 2) energy transportation, (pipeline, oil shipping and delivery companies) and/or 3) refineries and retail sales (Exxon, Mobil, Shell, So. Calif. Edison, N.Y. Edison, et al.) Eighty-two percent of all your dollars translates roughly into 33 of every of every 40 working hours you work is to pay for, in one way or another, the ultimate energy cost in the goods and services (transportation, heating, cooking, lighting) you purchase. Our current fossil energy sources also supply about 80 percent of the solid and airborne pollution which is slowly poisoning the planet. (See U.S. EPA report 1983 on coming world catastrophe from carbon dioxide imbalance caused by burning fossil fuels and lack of new, compounded by destruction of old, plant life).

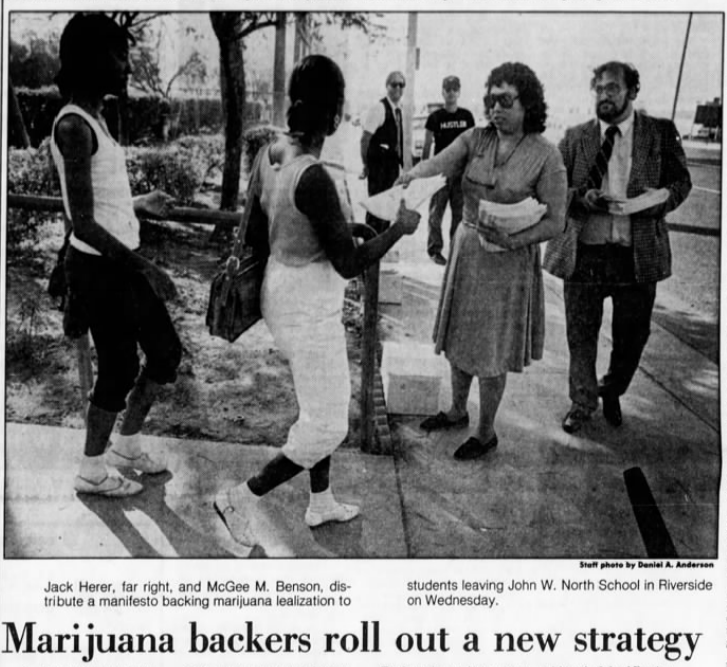

“Marijuana backers roll out a new strategy”, The San Bernardino County sun, San Bernardino, California, February 27th, 1986, pp. 17, 21

The cheapest substitutes for these expensive and wasteful energy methods is not wind or solar panels, nuclear, geo-thermal, and the like, but using the natural spreadout light of the sun to grow cellulose to be converted into methane gas and methanol wood alcohol. In the 1920s and ‘30s, most American cars and farm vehicles were sold with the option to run either on methanol or gasoline or both. During the gas shortages of World War II, methanol was widely used by farmers and even the military. It is still used by most racing cars today. Methanol does not pollute! When burned it emits only carbon dioxide and water vapors; and while growing it takes three times as much carbon dioxide out of the air before eventually putting (when burned) one-third of it back … whereas oil or coal only can pollute – never clean – because its source – vegetation or dinosaur – died millions of years ago. The early Oil Barons … aware in the Twenties of the possibilities of Ford’s methanol scheme (Henry Ford even grew marijuana on his estate after 1937 to prove the cheapness of methanol) and its cheapness, dropped and kept oil prices incredibly low – between $1.00 to $2.00 per barrel (there are 42 gallons in an oil barrel) for almost 50 years until 1970. So low, in fact, that no other energy source could compete with them … and when they were sure of the lack of competition, the price jumped to almost $40.00 per barrel in the next ten years. … In the 1920s-30s it was not cost effective to prepare large amounts of methanol, because of the cheapness of oil and because of the almost equal cost of heating the cellulose. But with modern improvements … this is no longer the case … The fuel – HEMP or other celuloses – for the methanol, while growing, provides oxygen to the air, consumes carbon dioxide for its cell structure, and does not pollute when burned. Science Digest reports that Cornell University in 1981-82 bioengineered an incredible new process which makes the ‘breakdown’ (composting) process by cellulase fifty times quicker and cheaper than the 1920s & 30s.” (1)

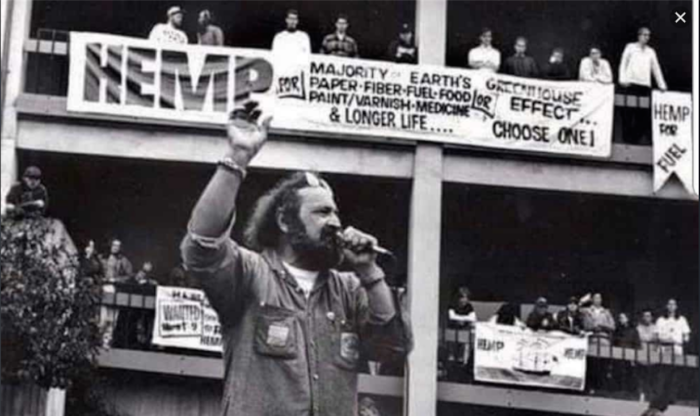

“For hemp lovers at the end of their rope, there’s legal plotting for pot,” Vancouver Sun, July 14th, 1994, p. 19

Everywhere this book travelled, it created hemp activists, or “Hempsters” as they were called. Some of those copies of his book made it up into Canada, and turned people like myself and Dana Larsen and Chris Bennett and Chris Clay and Marc Emery into Hempsters too. In fact, Marc Emery used to wear a button that said “Hemp Can Save the Earth” and shirts that said “HEMP CAN SAVE THE PLANET!”

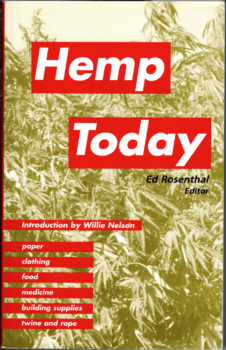

But then something happened in November 1994 that sucked all the energy out of the hemp movement. Ed Rosenthal produced a book called “Hemp Today”. (2)

In it, he and his fellow hemp fuel skeptic Dr. David Walker published two chapters claiming economically viable hemp ethanol fuel was unrealistic. Rosenthal’s chapter was called “Hemp Realities”, and Walker’s chapter was called “Can Hemp Save Our Planet?” Their arguments against Jack Herer’s and Lynn Osburn’s evaluation of hemp ethanol, summarized, are;

1) “… there are many plants which can produce a higher biomass on an annual basis.” (p. 76)

2) “Hemp producers cannot match the low prices of waste paper.” (p. 77)

3) “Hemp cannot be grown on the same field continuously without fertilizer.” (p. 79)

4) Hemp needs too much water and too much land to meet modern fuel needs (pp. 77-80).

5) “Energy production would yield a low profit to farmers.” (p. 81)

6) “It would be dangerous to rely on one species or even one method for virtually all energy needs.” (Ibid)

If one assumes we humans are able to transform society into a sustainable one, in which subsidies are switched from non-renewable energy to renewable energy, in which the health and environmental costs are factored into the cost of each product, and in which the red tape around industrial hemp is removed, then hemp ethanol will immediately become economically viable. None of these things are impossible, or even technically difficult – they could all be done quite easily, so long as there is enough public pressure to have them done. Obscenely rich people may need to be convinced that their control over the economy must be relinquished and their wealth spread out to millions of farmers so that humans can survive, but this difficult task is also not impossible. A sustainable society is just a matter of educating all of society about what the necessary steps must be taken.

The evidence against Rosenthal’s assertions – if we lived under those “sustainable society” conditions – can be summarized as follows;

“… there are many plants which can produce a higher biomass on an annual basis.”

There are two problems with this assertion that come up upon close inspection of the details. 1) Most authors who discuss hemp yield – including both Rosenthal and Osburn – are guilty of not being specific when they are talking about biomass yields – is it “green weight” or “dry weight” being discussed? Is it the entire plant, or just the stems? One must specify each time, or the numbers are meaningless. 2) High biomass by itself does not necessarily translate into a good fuel source – the evidence suggests that one must also factor in the cost per acre, the energy efficiency ratio (just how easily that biomass is turned into fuel), and the potential of that crop to be used as a carbon sink – so that the greenhouse effect can be reversed.

The truth is that few sources identify green/dry weight or whole plant/stems weight, which makes accurate estimates difficult. However, there is evidence from multiple sources to suggest that Rosenthal’s estimate for hemp biomass production of 3 to 5 tons per acre (p. 71) is low (3)

At the moment corn is the number one energy crop in the United States (4) – but only because corn is so heavily subsidized, (5) and hemp is so heavily over-regulated. For the last 20 years, the Canadian hemp economy has been under “tight controls”. (6) A minimum of 10 acres must be grown. (7) The hemp must test below 0.3% in THC. (8) The strain must be “approved”. (9) Hundreds of potentially profitable industrial strains are denied to farmers. (10) Hemp seed must be rendered non-viable and tested for viability. (11) In the US, those with criminal records for cannabis farming are not allowed to grow hemp. (12) This restriction was recently lifted in Canada – after unfairly excluding some farmers from industrial hemp jobs for 20 years. (13)

Breeders licenses – permitting access to the most economically rewarding element of industrial hemp farming and allowing farmers self-sufficiency and independence – are difficult to obtain. One needs the equivalent of a science degree and 10 years experience working under an accredited breeder. (14) US seed breeder licensing rules are different, but still onerous. (15) Hemp is so over-regulated, hemp seeds for human food is the only reliable market for it, because hemp seed and hemp seed oil is so valuable as a source of essential fatty acids that consumers will pay a premium price for it in spite of the added costs from the over-regulation. (16)

Hemp is a superior energy crop to corn for many reasons. Hemp: A) doesn’t need as much fertilizer or water as corn, switchgrass or other energy crops, (17) B) doesn’t require the expensive drying required of corn and sugar cane, (18) C) can be grown where other energy crops can’t, (19) D) has long been known to be the lowest-moisture highest-cellulose crop – ideal for fuel production. The hemp stalks are “over 75% cellulose” according to a 1929 paper from Schafer and Simmonds with more conservative estimates indicating the hurds being between 32% and 38% percent cellulose, while the bark is between 53% and 74%, (20) E) is much more energy efficient than corn. One estimate states that corn has a 34 percent energy gain, while hemp has a 540 percent energy gain. (21) This means hemp is nearly 16 times as efficient an energy crop as corn!

On top of all this, hemp is F) possibly the best carbon sink fuel crop in the world. What is a carbon sink? It’s a way to “reverse” the greenhouse effect and save the world, as hemp activist Chris Conrad explains;

“Each crop produces as much oxygen as it will later produce of CO2 if every bit of it is burned as fuel, creating a balanced cycle. Furthermore, hemp deposits 10 percent of its mass in the soil as roots and up to 30 percent as leaves which drop during the growing season. This means that some 20 to 40 percent more oxygen can be produced each season than will later be consumed as fuel – a net gain in clean air. Call it a ‘reverse greenhouse effect’.” (22)

Image from: NASA Releases Time-Lapse Video Of Depleting Arctic Ice Cap | BOOM https://www.youtube.com/watch?v=qHE0n5c6-6g

Image from: Arctic Sea Ice Near Historic Low; Antarctic Ice Continues Decline Released Tuesday, September 24, 2024 https://svs.gsfc.nasa.gov/14684/

More recent evaluations of hemp as a carbon sink consider it the “best possible option” (23) and “more efficient than agro-forestry” (24) and that it absorbs C02 “4 times faster than a forest”. (25) As one research team put it;

“As global CO2 levels rise, cannabis (hemp) plants grow larger naturally. For every ton grown above-ground, another half a ton of carbon is stored in the soil as root mass, where it belongs.” (26)

It is clear that hemp is the superior bio fuel crop – when all the factors that make a good biofuel crop are considered. It is only the fact that other crops are subsidized and hemp is over-regulated that prevents hemp from being economically competitive at this moment. This situation could change overnight, if somehow the public became aware of the fraud behind hemp over-regulation and the immediate environmental benefits that would occur if fossil fuels were replaced with hemp ethanol.

Image from: https://www.reddit.com/r/interestingasfuck/comments/3cb7vq/muir_glacier_alaska_1941_and_2004/

“Hemp producers cannot match the low prices of waste paper.”

Waste paper itself would be made from hemp instead of trees if the red tape around industrial hemp would be removed. Waste hemp paper would no doubt be used for many things, including both ethanol production and the manufacture of recycled paper. Ideally there would be a place to take the waste paper that wasn’t used for recycled paper – the cellulose manufacturing plant – which would also be where any other excess cellulose from other sources would be taken. But replacing all the gasoline in the world would require more than the cellulose that wasn’t already used in recycled paper – crops devoted to energy production would be required to meet these needs.

According to Rolling Stone magazine, (27) the United States spends $649 billion dollars on “direct and indirect subsidies for coal, oil and gas” – and another $599 billion on the Pentagon budget, a lot of which is spent on controlling the energy reserves of other countries. According to Forbes magazine, these fossil fuel subsidies are the main obstacle to transitioning to a sustainable energy economy. (28)

When those subsidies are switched over to renewable energy sources and when the health and environmental costs of each product is factored into the price and when the red tape around industrial hemp is removed, fossil fuels and non-renewable energy will suddenly become too expensive to produce and a massive demand for renewable energy sources – including hemp ethanol – will make hemp as a fuel crop suddenly viable.

Image from: “Workers harvest cannibis at a licensed farm in Tochigi Prefecture,” Photo: Juinichi Takayasu https://japanesemythology.wordpress.com/the-cannibis-hemp-heritage-of-japan-reblogged-article/

“Hemp cannot be grown on the same field continuously without fertilizer.”

This is true, but it is also true that hemp can provide it’s own fertilizer. There are two ways hemp can fertilize it’s own field. The first way is the old way – through “field retting” – letting the rain wash the soil nutrients off the stalks and into the field;

“If the crop is retted in the field, nearly all soluble nutrients are washed into the soil during retting (Dewey, 1913).” (29)

According to another source, hemp’s fertilization requirements are minimal;

“Once hemp begins to grow, it requires very little care. Fertilizers, especially those containing nitrogen, can help farmers achieve optimal fiber yields, but little else is required.” (30)

Organic sources of nitrogen include animal manures and guanos, waste from fish and poultry processing plants and animal slaughterhouses, and crops such as alfalfa, cottonseed and soybeans. (31) There is some indication that field retting to replace lost nitrogen may not be ideal, but this needs more research with different fertilization methods to be better understood. (32)

The second way hemp can fertilize its own field is through the creation of “biochar” – a fertilizer/waste product through the pyrolysis hemp ethanol fuel making process. The biochar is added to the field before the sowing of next year’s hemp seeds;

“Returning the biochar into the soil rather than removing it all for energy production reduces the need for nitrogen fertilizers, thereby reducing cost and emissions from fertilizer production and transport.” (33)

It is clear that the benefits of biochar have not fully been realized because hemp ethanol production has been hampered with over-regulation and unfair subsidies to hemp substitutes. With more intelligent subsidies and more reasonable regulations, the resulting conditions will allow research into retting and biochar fertilization techniques, which will result in hemp fertilization to reach its full potential.

Image from: https://themissouritimes.com/after-years-of-work-farmers-can-once-again-cultivate-industrial-hemp/

Image from: https://www.hemp-works.ca/farming

Image from: Hemp – The New Agricultural Frontier https://www.youtube.com/watch?v=Pun9cHdXDfs

Hemp needs too much water and too much land to meet modern fuel needs.

According to one source, the United States has 60 million acres of idle arable land. (34) According to another source, the United States has 52 million acres left fallow, 38.1 million acres for ethanol production (mostly from corn), 127.4 million acres for livestock feed, 21.5 million acres for wheat exports, 13.6 million for “cotton/non-food”, 62.8 million acres for other grain & livestock feed exports, 77.3 million acres for domestic food production, for a total 391.5 million acres of cropland. (35) Separate from all this land use is livestock grazing land – which is extensive. (36)

If the health and environmental costs of each product were factored into the price tag and over-regulation of hemp was removed, hemp would suddenly replace much of these other crops. Fallow land could be replaced with hemp ethanol farming that was either field retted or biochar-amended, in order to replenish soils while at the same time hemp would choke out all the weeds. Corn for ethanol would be replaced with hemp for ethanol – a much more water and energy efficient choice. Livestock – due to it’s environmental costs – would become more expensive, and hemp seed would then suddenly become a preferable source for protein – and one could get both hempseed and hemp ethanol from the same crop. Cotton – which is pesticide and water intensive – would be replaced with hemp for fabric. (37)

One estimate for how much US land is needed to produce enough biomass energy to meet US needs is “6-8% of the land area of the 48 contiguous 48 states”. (38) For comparison, 41% of US land is used to feed and graze livestock. (39) Another way to calculate the area needed is to start with the fact that an acre of hemp can produce the equivalent of a thousand gallons of gasoline. (40) In 2012, the people of the United States used 134 billion gallons of gasoline (41) down from a peak of 142 billion in 2007. At one thousand gallons per acre, this would require 134 million acres of hemp ethanol-growing land to replace. If you add up all the fallow land, corn ethanol land, cotton land and half the livestock feed land, you get 167.4 million acres – more than enough to become energy self-sufficient.

A willingness to factor in the health and environmental costs into the cost of each product is needed to evolve into a sustainable species. We are faced with being forced to consider the ecology, the environment and the wellbeing of ourselves, farmers and future generations in order to survive. Many indigenous cultures have these ecological considerations as foundations of their religious beliefs (42) – it’s not impossible to imagine a global culture emerging with the same ecological foundation within both it’s economic and spiritual communities.

Image from: https://bioresources.cnr.ncsu.edu/resources/use-of-byproduct-from-cellulosic-ethanol-production-as-an-additive-for-concrete-a-possible-win-win-strategy/

“Energy production would yield a low profit to farmers.”

When subsidies are transformed from permanent subsidies to fossil fuels into temporary subsidies to renewable energy – especially hemp ethanol – the economy will get the kick start it needs to quickly replace gasoline. And one can get hemp seeds and CBD and fertilizer from the exact same crop that’s being grown for fuel, making sure farmers enjoy not one but four revenue streams from the same crop.

Hemp is currently being evaluated by a Polish fuel corporation as a fuel crop;

“A government-owned petroleum firm in Poland has struck a deal to produce bioethanol from hemp. Grupa Lotos, one of the 10 largest fuel companies in Central Europe by sales, entered the agreement with the state-owned Institute of Natural Fibers and Medicinal Plants, Hemp Today reported.” (43)

There are already 17 cellulosic ethanol manufacturing plants operational or under construction in 14 different US states with little to no subsidies relative to fossil fuel subsidies, (44) while Canada has 30 ethanol manufacturing plants. (45) There would no doubt be more if subsidies are switched over from non-renewable energy to renewable energy. As the over-regulation of industrial hemp is eventually lifted, it can only become more profitable to provide hemp stalks as feedstock to the ever-expanding number of ethanol manufacturing plants.

Image from: https://www.dinafem.org/en/blog/hemp-based-race-car/

Image from: https://hashmuseum.com/en/collection/hemp-lifestyle/henry-ford/

Image from: https://www.researchgate.net/figure/Henry-Ford-demonstrated-his-hemp-car-on-impact-Ford-1940_fig1_314138191

Image from: https://themeaningofwater.com/2020/10/03/henry-fords-hemp-cars/

6) “It would be dangerous to rely on one species or even one method for virtually all energy needs.”

Perhaps suggesting “all” energy needs can be met with hemp is an exaggeration. But since hemp is probably the best fuel crop, and since cellulosic ethanol is the only carbon negative choice of all the renewable energy options, hemp is a key part of any transformation to a sustainable energy grid, and might make the difference between a vibrant bioethanol industry and a stagnant one. All the renewable energy systems – sun, wind, wave, geothermal and cellulosic ethanol – should be subsidized instead of non-renewable energy, so that humanity isn’t dependent on just one energy source. Hemp production may be limited by land or water availability or even a year of bad weather, so it makes sense to have many different renewable energy options available. Having said that, it can also be argued that, as a fuel source that can reverse the Greenhouse effect, be grown nearly anywhere on earth, stored in a tank, utilized when the sun isn’t shining and the wind isn’t blowing, and can provide food and medicine and weed control and fertilizer all at the same time – hemp has no equal.

Other fuel sources are carbon neutral, but only cellulosic ethanol can be carbon negative. And lithium car batteries have a huge carbon footprint and possible land-fill problems that cellulosic ethanol doesn’t. (46) Ethanol has the added benefit of requiring no cleanup in the case of a spill – it simply evaporates. (47) Hemp can even grow in sand (48) and help turn desert regions into farmland (49) – allowing energy independence for nearly every country on Earth, which would essentially end armed conflict over limited energy resources. No more oil wars. No more oil spills. No more climate destabilization. A $135 to $300 dollar conversion kit turns every gas powered car into a hemp ethanol powered car. (50) Hemp ethanol would be about 5 times cheaper than gasoline at the pump (51) – the conversion kit will pay for itself with just a few trips to the gas station.

There was one more thing Rosenthal was wrong about. In the Forward to Hemp Today, Rosenthal stated that “the market” would decide if hemp was going to be successful or not;

“Hemp has jumped from magazines such as Britain’s The Ecologist and High Times in the U.S., to the press wires, TV, and national journals. Much of this media attention has accepted the ‘hemp hype’ without investigation. Recent books have focused on hemp’s past history and its idealized potential. One popular volume even claims that this plant alone can save the world from ecological disaster. … Will it help lead us to a greener future or is it just a pipedream? The market will decide in the next few years.” (52)

The fact is, it wasn’t “the market” forces that determined the shape of the hemp economy, rather, it was over-regulation based on Reefer Madness. There was one opportunity to challenge this over-regulation in 1997. Unfortunately, another pioneer of the cannabis movement – Dave Watson – was there to make sure the regulations would not be challenged.

Image from: HempenRoad, Pioneers in Vancouver – Producer’s Remix and Annotations, DaveO Storytime https://www.youtube.com/watch?v=aSPWOW4FAAQ

Dave Watson was a man who was well respected in the pot movement. Watson was the Chairman of the International Hemp Association and president of Hortapharm, the Dutch company that provided G.W. pharmaceuticals with all their cannabis genetics. His alias was “Sam the Skunkman” in growers circles. Watson was busted in the US city of Santa Cruz and then appeared in Holland one month later with hundreds of thousands of amazing pot seeds to sell. He also magically received the “only license to study medical cannabis in Holland.” He certainly had some powerful, mysterious friends. (53)

Watson came to Vancouver to speak at the Commercial & Industrial Hemp Symposium on February 19th, 1997 (54) – where the Health Canada – the government agency responsible for the new hemp regulations – came to announce the “legalization” of industrial hemp. The tight controls hemp was placed under guaranteed a seed breeder monopoly – you needed to have ten years apprenticeship underneath another licensed breeder plus a science degree. And Dave Watson was there to sell the community these regulations as being necessary. The way Watson prevented there being any discussion of the over-regulation/monopoly at the Hemp Symposium was to argue that any such talk was “marijuana issue”, and they were “separating the issues”. During the Q and A part of his talk, I asked a question;

“My concern is farmers having self-sufficiency … my question to you is, given the proven environmental and health benefits of hemp and the necessity that we get these benefits now, and given these regulations hurt hemp farming, do you feel that it is cowardly and maybe even immoral that people in the hemp industry don’t speak up against these unnecessary restrictions?”

Mr. Watson was unimpressed with my question, and responded thus;

“Well do you think it is the proper thing to do to put a millstone around the hemp industry by forcing them to legalize marijuana for you?

“Not for me. Not for me. But so that farmers don’t have to go to this company and that company to beg them for seed, instead of growing our own seeds and having self-sufficiency. Why should we have to kowtow to these obviously irrational (and maybe genocidal) interests?”

“My personal opinions don’t really matter in this issue but I think there are to separate issues … one is industrial hemp and one is recreational and medicinal cannabis – they don’t belong together.”

“You heard my question.”

“We are separating the issues, sir. This isn’t a conference to deal with the other.” (55)

And thus Watson prevented the one real opportunity of over-regulation of industrial hemp being challenged in a public setting in Canada – if not all of North America. Instead of “the market” deciding what the potential for industrial hemp would be – as Ed Rosenthal said would happen – the Canadian government – with the help of Dave Watson – decided instead.

It should be noted that the International Hemp Association – of which Dave Watson was Chairman – did publish a cursory protest letter to Health Canada in early 1998, arguing for slightly looser regulations and slightly higher THC levels, but did not question the premise that hemp seed breeding should be limited to professionals (in fact it was argued that farmers should not be able to save, share, trade and sell their own seeds) and did not question the treatment of cannabis as a hard drug;

“Enforcement under a system similar to Europe will be nearly failure proof, if the new Canadian regulations follow Europe’s lead. The various European systems require that only certified hemp varieties can be purchased for sowing and only from a licensed seed seller, by a licensed grower with a declared end use for the crop. This system has proven quite effective everywhere it is used.” (56)

It’s “effectiveness” in preventing industrial hemp from achieving it’s true potential can be attested to by the lack of hemp paper, hemp clothing, hemp plastics, hemp concrete, hemp pressed particle board and hemp ethanol available for purchase, in spite of hemp being “legal” in Canada for the past 23 years.

It’s for these reasons that Ed Rosenthal was wrong about hemp ethanol, and Jack Herer was right. It turns out that Herer was correct when he said “I don’t know if hemp is going to save the world, but it’s the only thing that can.” (57)

1. Jack Herer, Emperor Wears No Clothes, First Revised Edition, Queen of Clubs publishing, Seattle, Washington, December, 1985, pp. 65-66

2. Hemp Today, Ed Rosenthal, editor, Quick Trading Company, San Francisco, 1994

3. In the 11th edition of the Emperor, writer Lynn Osborn suggests Rosenthal’s estimate for hemp biomass production is low; “His 3.5 tons per acre is at the extreme low end of the yields that have been reported; eighteen tons per acre is at the high end.” Jack Herer, “The Emperor Wears No Clothes”, 11th ed., AH HA publishing, Van Nuys, California, 2000, p. 250

Feasibility of Industrial Hemp Production in the United States Pacific Northwest, 1998, Agricultural Experiment Station, Oregon State University

“A yield of 19.4 tonnes/ha (8.7 tons/acre) was recently reported in the Netherlands using a late maturing Japanese landrace (Van der Werfet aL, 1995b).”

https://catalog.extension.oregonstate.edu/sites/catalog/files/project/pdf/sb681.pdf

This source then goes on to explain how different approaches to increasing hemp yield are likely to achieve even better results. As does this source:

“Research conducted by Dr. H.M.G. van der Werf showed that fiber hemp yields can be increased by about 30% by growing very late-flowering cultivars at a relatively low density (<300 plants /m2). The crop self-thins due to inter-plant competition, and it is harvested late in September.” Hemp Husbandry, Robert A. Nelson,

Internet Edition, Copyright 2000, https://www.hempbasics.com/hhusb/hh2cul.htm#HH23

“The Oregon study summarizes hemp yields reported by researchers from various countries since the 1900’s (Ehrensing). Early in this century, U.S. dry-stem yields ranged from 2 to 12.5 tons per acre, but averaged 5 tons per acre under good conditions. Research trials in Europe during the last four decades had dry-matter yields that ranged from 3.6 to 8.7 tons per acre. In the Netherlands, research trials during the late 1980’s reported dry-stem yields of 4.2 to 6.1 tons per acre.

Recent commercial production in England produced average dry-matter yields of 2.2 to 3 tons per acre on several thousand acres over several years. Experimental production in Canada during 1995 and 1996 yielded 2.5 to 3 tons of dry stems per acre. According to the study, some of the variation in yield can be attributed to different measurement practices. For example, European authors generally report total above-ground dry matter, including stems, leaves, and seed, versus the dry-stem yields reported by other researchers.” Industrial Hemp in the United States: Status and Market Potential–Potential U.S. Production and Processing, USDA, 2000 https://www.ers.usda.gov/publications/pub-details/?pubid=41757

Green stalks = 15,000 pounds per acre. Dry stalks = 10,000 pounds per acre.

Dry stalks, after dew retting: 6000 pounds per acre. Dewey, 1913, p. 336 1 US ton equals 2000 pounds, therefore dry stalks post-dew retting equals 3 tons/A

https://hempology.org/img/1913%20USDA%20YEARBOOK%20HEMP%20PGS%20283-346%20082008.pdf

“Dempsey (1975) describes the various components of the total hemp plant biomass yield. He estimates that a good yield of green hemp plants would be about 40,000 kg/ha (36,000 lbs/A or 18 tons/A). The yield of green stems would be approximately 28,000 kg/ha (28 mt/ha, 24,976 lbs/A, or 12.49 tons/A.) These green-weight yield data are similar to Osburn’s 10 tons/A estimate. The total hemp plant dry weight would be about 16,500 kg/ha (14,700 lbs/A or 7.4 tons/A). Of that dry weight, about 10,500 kg/ha (9,400 lbs/A or 4.7 tons/A) would consist of dried stems (Dempsey, 1975).” Hemp Today, Ed Rosenthal, editor, Quick Trading Company, San Francisco, 1994, p. 99

4.“Corn cobs and corn stover (the leaves, stalks, and cobs) are the most popular agricultural biomass.”

https://en.wikipedia.org/wiki/Cellulosic_ethanol#Feedstocks

5. ”The federal government spends more than $20 billion a year on subsidies for farm businesses. About 39 percent of the nation’s 2.1 million farms receive subsidies, with the lion’s share of the handouts going to the largest producers of corn, soybeans, wheat, cotton, and rice.” https://www.downsizinggovernment.org/agriculture/subsidies

6. Hemp, Mark Bourrie, Key Porter Books Limited, Toronto, Canada, 2003, p. 67

7. Arthur Hanks, Canadian Hemp Trade Alliance, personal communication, 2006

https://cannasystems.ca/pdf/ListofApprovedCultivars2019.pdf

Producers will still be required to use approved varieties of certified seed that has been purchased from a member of the Canadian Seed Growers Association.9

10. Arthur Hanks, Canadian Hemp Trade Alliance, personal communication, 2006; See also: “In 1993 the VIR, with the sole support of the IHA, began a 4 year program to preserve and evaluate its Cannabis germplasm. The collection consists of 397 accessions of Cannabis seeds from three basic eco-geographical groups: Northern, Middle, and Southern, collected from 16 nations (Table 1). The collection represents wild and traditional cultivated varieties as well as products of plant improvement programs. The vast majority of the accessions are classified as low-THC chemotypes of Cannabis sativa L.” Maintenance of Cannabis germplasm in the Vavilov Research Institute Gene Bank – 1993, Nikolai Lemeshev1, Lyudmila Rumyantseva1 and Robert C. Clarke2 http://www.internationalhempassociation.org/jiha/iha01101.html

“Thanks to the implementation of the joint VIR/IHA project, in 1993-1995 a total of 252 hemp accessions were reproduced. All of the samples were either very old seed reproductions (before 1989) or had a small number of seeds. Successful reproductions were received from 134 threatened accessions. In 55 accessions very small number of seeds were produced, so it would be necessary to repeat regeneration. In addition, repeated regeneration is required for 65 accessions, which yielded insufficient seed quantities in 1991-1992 before the VIR/IHA project started.” Maintenance of Cannabis germplasm in the Vavilov Research Institute Gene Bank – 1995, Sofia Kutuzova1, Lyudmila Rumyantseva2 and Robert C. Clarke3

http://www.internationalhempassociation.org/jiha/iha03108.html

“The Cannabis collection preserved at the VIR consists of 496 accessions, representing the wide global diversity of this crop.” Maintenance of Cannabis germplasm in the Vavilov Research Institute Gene Bank – 1996, Sofia Kutuzova 1, Lyudmila Rumyantseva 1, Sergey Grigoryev 1 and Robert C. Clarke 2 http://www.internationalhempassociation.org/jiha/jiha4108.html

13. https://www.grainews.ca/2018/10/02/canadian-hemp-growers-look-forward-to-relaxed-rules/

14. Arthur Hanks, Canadian Hemp Trade Alliance, personal communication, 2006

See also: “Plant Breeder: To be granted recognition as a fully qualified Plant Breeder an individual must meet the following criteria:

- Ph.D. in plant breeding plus 1 year independent plant breeding experience in a country participating in the OECD Seed Schemes;

– or –

- M.Sc. in plant breeding plus 3 years independent plant breeding experience in a country participating in the OECD Seed Schemes;

– or –

- B.Sc. in Agriculture plus 10 years on-the-job training (five years in a country participating in the OECD Seed Schemes) plus

release of a recognized variety; – or4. Ph.D. or M.Sc. in a closely related field/discipline plus seven years on-the-job training, including at least one year’s training in a country

participating in the OECD Seed Schemes. The number of years of training may be reduced depending on the amount and relevancy

of formal training in plant breeding and/or closely related field(s)/ discipline(s);

– or –

5. Ph.D., M.Sc., or B.Sc. in an unrelated field/discipline plus qualification as an Associate Plant Breeder plus successful completion of graduate level course work or equivalent in plant breeding.”

https://seedgrowers.ca/wp-content/uploads/Form43A_Application-For-Breeder-Recognition_20080417.pdf

16. “Focus on where you are going to sell your product and seek contracts with food producers. If you can secure this, you will be able to confidently move ahead with planting your crops,”

17. “Hemp requires a plentiful supply of moisture throughout its growing season, especially during the first 6 weeks. After it has become well rooted and the stalks are 20 to 30 inches high it will endure drier conditions …”

https://www.hempbasics.com/hhusb/hh2cul.htm#HH23

“Compared with other crops, hemp requires a low level of irrigation and fertilizers after its establishment (Amaducci et al., 2008b; Gandolfi et al., 2013).” Valorisation of hemp inflorescence after seed harvest: Cultivation site and harvest time influence agronomic characteristics and essential oil yield and composition, IND CROP PROD, Jul 2019, Roberta Ascrizzi, Lucia Ceccarini, Silvia Tavarini, […], Luciana G. Angelini

View Researchgate article here.

“Unlike flax, hemp is naturally resistant to most pests and diseases and actually acts as a deterrent to weeds. Furthermore, unlike kenaf and other fiber crops, hemp withstands most changes in temperature, making it suitable for growth in many areas.” Dwyer, Susan David (1998) “The Hemp Controversy: Can Industrial Hemp Save Kentucky?,” Kentucky Law Journal: Vol. 86 : Iss. 4 , Article 12.

https://uknowledge.uky.edu/klj/vol86/iss4/12

“Canadian hemp farmers already profit around $250 an acre—up to ten times as much as they’d be getting for corn crops. While using about half the water, which actually allows dry cropping in places that have been ravaged by drought.”

“Can Hemp Really Save the World?” David Bienenstock, Apr 7 2014 https://www.vice.com/en_us/article/mv5b8x/the-great-hemp-experiment-begins?fbclid=IwAR0z-tCILMAp7BuPGtAFIXqox9i96PiAK7N3bgz81_7fbxP5VmmU8KkE1Wc

18. “The Hawaiian Natural Energy Institute (’s) … 1990 report concluded that thermochemical (pyrolytic) production of methanol from biomass is the most economical alternative for transportation fuel. They also confirmed Stanford Research Institute’s conclusion from the late seventies that woody or low moisture herbaceous plants are the most efficient biomass resource for thermochemical conversion into liquid fuels such as methanol. It is the cellulose in low moisture herbaceous and woody plants that provides the hydrocarbons necessary for fuel production. Hemp stalks are over 75% cellulose. Hemp is both a low moisture herbaceous and a woody plant.” Jack Herer, “The Emperor Wears No Clothes”, 11th ed., AH HA publishing, Van Nuys, California, 2000, p. 252

19. “With the ability to be grown at all but the very coldest latitudes, Cannabis could form the basis of an internationally distributed (yet locally determined) fuel industry. The chemical composition (high cellulose) and physiology of

Cannabis make it an ideal feedstock for ethanol production in comparison to the starch based crops currently used in the US and South America (Lorenz and Morris, 1995).” “Could Cannabis Provide an Answer to Climate Change?”

Marc R. Deeley, Journal of Industrial Hemp, Vol. 7(1) 2002 http://www.internationalhempassociation.org/pdf/J237.pdf?fbclid=IwAR15I56Tk1Lu6ZrSa4rdQIPnyw1pRDDnwCwVQ6stUPm9HUqCnGVVtZ8-BsU

“Hemp can flourish in conditions considered less than optimum, and will usually produce more than competitor crops in such instances.”

https://sensiseeds.com/en/blog/hemp-plastics-made

“Biogas from hemp turned out to be a high yielding alternative to the currently dominating renewable transportation fuels produced from crops grown in Sweden: ethanol from wheat and biodiesel from rapeseed.”

https://www.sciencedirect.com/science/article/pii/S0961953410003958

“This study examined the energy yield of hemp (Cannabis sativa L.) cultivated for energy purposes under cold climate conditions in Northern Europe. … As a solid fuel, the adjusted biomass energy yield of hemp was 120% higher than that of wheat straw and similar to that of reed canary grass.”

https://www.sciencedirect.com/science/article/pii/S096195341100208X

20. For the “over 75% cellulose” stat, please see: “Physical and Chemical Characteristics of Hemp Stalks and of Seed Flax Straw”, E. R. Schafer F. A. Simmonds Ind. Eng. Chem. 1929, 21, 12, 1241-1244, Publication Date: December 1, 1929

https://doi.org/10.1021/ie50240a025

“For a start, cellulose content of hemp hurds has been found to vary between 32 and 38 % (Bedetti and Ciaralli 1976, van der Werf 1994). Possibly, Herer confuses the hurds, which form the woody core of the hemp stem, with the bark, which forms the outer layer of the hemp stem. The bark contains the long bast fibres which are used in textile manufacturing. The cellulose content of the bark is much higher than that of the core. It has been found to lie between 53 and 74 % (Bedetti and Ciaralli 1976, van der Werf 1994).” “Hemp facts and hemp fiction”, Hayo M.G. van der Werf, International Hemp Association, Postbus 75007, 1070 AA Amsterdam, the Netherlands, http://www.hempfood.com/IHA/iha01213.html

“There is much work to be done as far as cultivating plants with high cellulose content to be used for fuel. The much-maligned hemp plant (a fibrous industrial version of marijuana) has been known to provide cellulosic stands 14 feet tall when irrigated in good soils. With cellulose yields of five tones or more per acre, hemp could be a new contender in the energy field, possibly yielding 900 to 1000 gallons per acre in six months.” ALCOHOL CAN BE A GAS, David Blume, The International Institute for Ecological Agriculture, Santa Cruz, California, 2008, p. 133

21. “There is no question that “corn ethanol is energy efficient.” It has “an energy ratio of 1.34 [, which means] for every BTU dedicated to producing ethanol there is a 34 percent energy gain. Unfortunately, corn puts high demands on land and water resources, and producing biofuel from it is energy and resource-intensive. Industrial hemp, by comparison, because of its high cellulose content has an estimated 540 percent energy gain.”

THE LEGALIZATION OF INDUSTRIAL HEMP AND WHAT IT COULD MEAN FOR INDIANA’S BIOFUEL INDUSTRY Nicole M. Keller, 2013, p. 577

https://pdfs.semanticscholar.org/f266/e9bbd511c361daa38c4853f075bee54a6886.pdf

See also: “Perennial herbaceous plants such as switchgrass (Panicum virgatum L.) are being evaluated as cellulosic bioenergy crops. Two major concerns have been the net energy efficiency and economic feasibility of switchgrass and similar crops. … Switchgrass produced 540% more renewable than nonrenewable energy consumed.”

Net Energy of Cellulosic Ethanol from Switchgrass

Marty R. Schmer, USDA-ARS, University of Nebraska-LincolnFollow

Kenneth P. Vogel, University of Nebraska-LincolnFollow

Robert B. Mitchell, University of Nebraska-LincolnFollow

Richard K. Perrin, University of Nebraska-Lincoln

Published in Proceedings of the National Academy of Sciences (January 15, 2008) 105(2): 464-469. https://digitalcommons.unl.edu/ageconfacpub/106/

https://digitalcommons.unl.edu/cgi/viewcontent.cgi?article=1110&context=ageconfacpub https://cropwatch.unl.edu/documents/Net%20Energy%20of%20Cellulosic%20Ethanol%20from%20Switchgrass.pdf

22. Chris Conrad, “Hemp – Lifeline to the Future”, Creative Xpressions Publications, Novato, California, 1994, p. 72

23. “Utilisation of biomass in both the energy and transport sectors holds several benefits not least because these can be used to offset or substitute directly for fossil fuels thereby reducing emissions of Greenhouse Gases (GHGs), particularly carbon dioxide (CO2), while simultaneously sequestrating atmospheric CO2 via photosynthesis by creating and enhancing terrestrial “carbon sinks” (IPCC, 1996b). Following the United States’ refusal to consider serious reductions in their emissions, “carbon sinks” are now a universally agreed method to achieve atmospheric carbon reductions as set out in the Kyoto Protocol. The IPCC (1996b) considers fast-growing hardwoods to be the best possible option. Cannabis is, therefore, perfectly placed to be utilised in this area given its chemical composition, which is comparable to that of a hardwood (van der Werf et al., 1999) and rapid growth cycle compared to other high cellulose content organisms.”

Marc R. Deeley, Could Cannabis Provide an Answer to Climate Change? Journal of Industrial Hemp, Vol. 7(1), 2002, pp. 133-138

https://www.tandfonline.com/doi/abs/10.1300/J237v07n01_11

See article beginning at page 133: http://www.internationalhempassociation.org/pdf/J237.pdf

24. “One hectare of industrial hemp can absorb 22 tonnes of CO2 per hectare. It is possible to grow to 2 crops per year so absorption is doubled. Hemp’s rapid growth (grows to 4 metres in 100 days) makes it one of the fastest CO2-to-biomass conversion tools available, more efficient than agro-forestry.”

https://hemp-copenhagen.com/images/Hemp-cph-Carbon-sink.pdf

25. “These fuels have great advantages over the current bio-fuels on the market today, which are energy, land and resource intensive. ‘Hemp is seen as an environmentally friendly alternative to cotton, since growing hemp uses far less irrigation and little or no pesticide, herbicide or fertilizer. Hemp can also absorb carbon monoxide 4 times faster than a forest,’ the journalist explains in the following video.”

Dr. Wing Sung on New Hemp Fiber, Dec 5, 2008 at 2:10 of this video https://www.youtube.com/watch?v=2Gl-UpvnipU&feature=emb_logo

http://crrh.org/news/content/canada-research-cellulosic-ethanol-sustainable-feedstock

26. “Cannabis is an ancient “C3” plant species which means it can absorb CO2 up to 1200 parts per million. Our modern “C4” plants reach saturation and do not absorb additional CO2 beyond 500 ppm as cannabis does. Cannabis has this remarkable ability to absorb CO2 directly from the atmosphere. As global CO2 levels rise, cannabis (hemp) plants grow larger naturally. For every ton grown above-ground, another half a ton of carbon is stored in the soil as root mass, where it belongs. This creates a “carbon negative” opportunity to capture CO2 for the life of the products made from the crop.” CannaSystems Canada Inc., White Paper, p. 11

https://cannasystems.ca/pdf/CannaSystemsWhitePaper.pdf

27. “Study: U.S. Fossil Fuel Subsidies Exceed Pentagon Spending

The world would be richer and healthier if the full costs of fossil fuels were paid, according to a new report from the International Monetary Fund,” TIM DICKINSON

“The IMF found that direct and indirect subsidies for coal, oil and gas in the U.S. reached $649 billion in 2015. Pentagon spending that same year was $599 billion.”

28. Fossil Fuel Subsidies And Impact Greenwashing Are Stalling The Energy Transition”, Wal van Lierop

29. https://catalog.extension.oregonstate.edu/sites/catalog/files/project/pdf/sb681.pdf

https://hempology.org/img/1913%20USDA%20YEARBOOK%20HEMP%20PGS%20283-346%20082008.pdf

“The retting process of the straw allows nutrients like nitrogen and potassium to be leached out and accumulate in the soil under the swaths. Of all the nutrients, phosphorus has the highest percentage stored in the seed. The other nutrients are more inclined to be stored in the stalks.”

http://www.hemptrade.ca/eguide/production/nutrient-use

30. Dwyer, Susan David (1998) “The Hemp Controversy: Can Industrial Hemp Save Kentucky?,” Kentucky Law Journal: Vol. 86 : Iss. 4 , Article 12.

https://uknowledge.uky.edu/klj/vol86/iss4/12

31. “Hemp has need for nitrogen to grow well, but this can be satisfied by manure, which is environmentally advantageous where there is a surplus of manure”

A comparison of the biodiversity friendliness of crops with special reference to hemp (Cannabis sativa L.), Suzanne Montford, Journal of the International Hemp Association, Vol. 6 No. 2 December 1999

See also:

32. “Nevertheless, hemp production, including a field retting period, may cause problems of nitrate leaching in water catchments when high amounts of lost plant material is rapidly decomposed in Autumn. Hence, cropping fiber hemp as silage without field retting should be tested as an alternative method.” Hemp: a ground water protecting crop? Yields and nitrogen dynamics in plant and soil Katja Hendrischke1, Thomas Lickfett1, and Hans-Bernhard von Buttlar,, Journal of the International Hemp Association, Vol. 5 No. 1 June 1998http://www.internationalhempassociation.org/jiha/jiha5109.html

33. https://en.wikipedia.org/wiki/Biochar

35. https://www.bloomberg.com/graphics/2018-us-land-use/

36. “A 212-page online report published by the United Nations Food and Agriculture Organization says 26 percent of the earth’s terrestrial surface is used for livestock grazing.”

“I am not suggesting that we plant hemp on all US pastureland though hemp will grow quite well on it. Raising livestock on pastures is incredibly inefficient land use, but we make it profitable anyway because a good many of us enjoy eating meat. When we desire fresh air and a stable ecosystem in a clean environment as much as we enjoy eating meat we will make energy farming more than profitable.”

Lynn Osburn, quoted in Jack Herer, “The Emperor Wears No Clothes”, 11th ed., AH HA publishing, Van Nuys, California, 2000, p. 250 http://www.digitalhemp.com/eecdrom/HTML/EMP/AA/ECH19.HTM#response

37. “In terms of water consumption, cotton requires 9,758 kg of water per kg, while hemp requires between 2,401 and 3,401 kg of water per kg.” Ecological Footprint and Water Analysis of Cotton, Hemp and Polyester, Nia Cherrett, John Barrett, Alexandra Clemett, Matthew Chadwick, M.J. Chadwick, 2005, Stockholm Environment Institute https://mediamanager.sei.org/documents/Publications/SEI-Report-EcologicalFootprintAndWaterAnalysisOfCottonHempAndPolyester-2005.pdf

“The water footprint of cotton textile is more than three times larger than the water footprint of industrial hemp textile. Products of industrial hemp textile have many advantages over products of cotton textile: industrial hemp is four times softer, industrial hemp is three to eight times stronger, industrial hemp is much more durable, industrial hemp is flame retardant, industrial hemp is not affected by UV rays, industrial hemp is very breathable but also very moisture absorbent. The production areas of cotton textile are for a greater part in water scarce regions in the world. Industrial hemp is mainly grown in parts of the world were a little or no water scarcity is, so production of industrial hemp is less stressful for the environment.”

Global Water Footprint of Industrial Hemp Textile, J. Averink, September 2015, University of Twente, Netherlands https://essay.utwente.nl/68219/1/Averink,%20J.%200198501%20openbaar.pdf

“Conventionally grown cotton uses more insecticides than any other single crop and epitomizes the worst effects of chemically dependent agriculture. Each year cotton producers around the world use nearly $2.6 billion worth of pesticides — more than 10 per cent of the world’s pesticides and nearly 25 per cent of the world’s insecticides. Cotton growers typically use many of the most hazardous pesticides on the market including aldicarb, phorate, methamidophos and endosulfan. Cotton pesticides are often broad spectrum organophosphates — pesticides originally developed as toxic nerve agents during World War II — and carbamate pesticides.” https://www.ethical.org.au/3.4.2/get-informed/issues/cotton-pesticides/

38. 18.19.ENERGY FROM BIOMASS: “Meeting U.S. demands for oil and gas would require that about 6-8% of the land area of the contiguous 48 states be cultivated intensively for biomass production.”

39. “… Bloomberg article states that when you combine land used for animal feed and actual grazing land itself, a whopping 41% of US land (nearly 800 million acres) is used to feed farm animals.”

40. “Colorado biomass fuels consultant Agua Das and Colorado School of Mines chemical engineer Thomas B. Reed reported that an acre of hemp can produce power equivalent to a thousand gallons of gasoline.”

Hemp Bound, Doug Fine, Chelsea Green Publishing, White River Junction, Vermont, 2014, p. xxx; See also: http://crrh.org/news/content/biomass-fuels-hemp

http://crrh.org/downloads/Biomass-Fuels-From-Hemp.pdf

41. http://www.earth-policy.org/data_highlights/2013/highlights38

42. https://e360.yale.edu/features/native-knowledge-what-ecologists-are-learning-from-indigenous-people

43. https://hempindustrydaily.com/polish-petroleum-firm-inks-deal-to-produce-biofuel-from-hemp/

44. https://en.wikipedia.org/wiki/Cellulosic_ethanol#Cellulosic_ethanol_commercialization

46. “Lithium Batteries’ Dirty Secret: Manufacturing Them Leaves Massive Carbon Footprint: Once in operation, electric cars certainly reduce your carbon footprint, but making the lithium-ion batteries could emit 74% more CO2 than for conventional cars.” Bloomberg, OCT 16, 2018, https://www.industryweek.com/technology-and-iiot/article/22026518/lithium-batteries-dirty-secret-manufacturing-them-leaves-massive-carbon-footprint “At the moment, recycling lithium-ion car batteries is long-winded and inefficient. In some cases, a battery is shredded and separated into its components, where some materials such as metal may be able to be reused. Or, if it may still hold some charge, it is frozen in liquid nitrogen and smashed into bits. It is estimated that only 20% of the materials can be reused after these processes.” https://www.thegreenage.co.uk/tech/environmental-footprint-electric-cars/

47. MBRIA — There will be no action taken to clean up the site of an ethanol spill from a railroad derailment, but monitoring wells will be installed. State pollution officials said boring tests from the site near Cambria in Blue Earth County showed the soil is naturally very high in organic material, which will help speed the evaporation of ethanol and a small amount of gasoline. And they found the ethanol is being contained well by clay under the topsoil and there has been no migration of pollutants and no pollutants detected in the Minnesota River. ‘They think is will naturally evaporate rather quickly,’ said Nancy Miller, a spokeswoman for the Minnesota Pollution Control Agency. Six Dakota, Minnesota and Eastern Railroad cars derailed Nov. 22 with 30,000 gallons of ethanol, mostly from one tanker, spilling into the dry bed of the Little Cottonwood River.” http://mankatofreepress.com/local/x519261231/Ethanol-spill-decision-No-cleanup-required https://www.cannabisculture.com/content/2010/05/23/hemp-ethanol-spill-would-just-evaporate/

48. Marijuana Medicine, Christian Ratsch, Healing Arts Press, Rochester, Vermont, 2001, p. 64

49. “How hemp could save Afghanistan and the world”, Reverend Damuzi, April 12, 2005 https://www.cannabisculture.com/content/2005/04/12/4272/ “Growing hemp in the desert”, Jun 10, 2019 https://www.havasunews.com/growing-hemp-in-the-desert/article_67d77e50-8c11-11e9-9c03-138d6e48f34d.html “The ‘underground forests’ that are bringing deserts to life”, Geoffrey Lean, 12 Jul 2013, https://www.telegraph.co.uk/news/earth/10176217/The-underground-forests-that-are-bringing-deserts-to-life.html “How to reclaim deserts and reverse climate change”, JO · PUBLISHED JULY 11, 2015 · UPDATED AUGUST 22, 2017 http://healingearth.info/reclaim-deserts-reverse-climate-change/

50. https://www.autoethanol.eu/

https://fuelflex.international/shop/kit-e85/flex-fuel-kit-2-cylinders

51. “According to biofuel expert Tim Castleman, hemp ethanol could be produced for 1.37 per gallon plus the cost of the feedstock, with technological improvements and tax credits reducing the price another dollar or so per gallon!” CIFAR Conference XIV, “Cracking the Nut: Bioprocessing Lignocellulose to Renewable Products and Energy”, June 4, 2001

http://fuelandfiber.com/Hemp4NRG/Hemp4NRGRV3.htm (dead link) http://pot-facts.ca/hemp-ethanol-is-about-five-times-cheaper-than-gasoline/

“Hemp Cellulose for Ethanol: Another approach will involve conversion of cellulose to ethanol, which can be done in several ways including gasification, acid hydrolysis and a technology utilizing engineered enzymes to convert cellulose to glucose, which is then fermented to make alcohol. Still another approach using enzymes will convert cellulose directly to alcohol, which leads to substantial process cost savings.

Current costs associated with these conversion processes are about $1.37[vi]per gallon of fuel produced, plus the cost of the feedstock. Of this $1.37, enzyme costs are about $0.50 per gallon; current research efforts are directed toward reduction of this amount to $0.05 per gallon. There is a Federal tax credit of $0.54 per gallon and a number of other various incentives available. Conversion rates range from a low of 25-30 gallons per ton of biomass to 100 gallons per ton using the latest technology.”

52. Hemp Today, Ed Rosenthal, Quick American Archives, Oakland California, 1994, pp. xv-xvi

53. “The Mysterious Mr. Watson”, Steven Hager, September 9, 2018 https://stevenhager.net/2018/09/09/16076/ See also: “Who is the real King of Cannabis?”, Steven Hager, September 9, 2018 https://stevenhager.net/2018/09/09/who-is-the-real-king-of-cannabis/ DAVID WATSON AKA SAM THE SKUNKMAN AKA SAM SELEZNY AKA Dr. FrankenbeanStein AKA Dr. FrankenWeedStein AKA King of Snitchcraft https://pastebin.com/rDUaWDYK

54. Canada’s Commercial and Industrial Hemp Symposium http://www.internationalhempassociation.org/jiha/jiha4118.html

55. Transcripts of the Commercial & Industrial Hemp Symposium, February 19th, 1997, quoted in Vansterdam Comix, David Malmo-Levine & Bob High, WEEDS, Vancouver, 2018, pp. 151-157 See also: The HempenRoad (1997) ~ Documentary about industrial cannabis and medical marijuana @ 1:11:39 https://vimeo.com/122077349

56. IHA Reply to Proposals for Canadian Industrial Hemp Regulations, Submitted to Jean Peart, Manager, Hemp Project, Health Canada by the International Hemp Association on January 5, 1998 http://www.internationalhempassociation.org/jiha/jiha4222.html

57. “Hemp Is Finally Legal. Let’s See if It Can Save the World”, David Bienenstock

https://www.leafly.ca/news/politics/hemp-legalization-in-the-farm-bill-of-2018-history-politics